The Basics of Paper-making – Part 1: Integrated and non-integrated paper mills

Paper-making uses some unusual terms that aren’t common in general flexible packaging. This blog is part of a series that will make up a quick reference guide to help you understand the basics of paper-making. In part one of our series, we’ll cover the difference between integrated and non-integrated paper mills.

Integrated Paper Mills

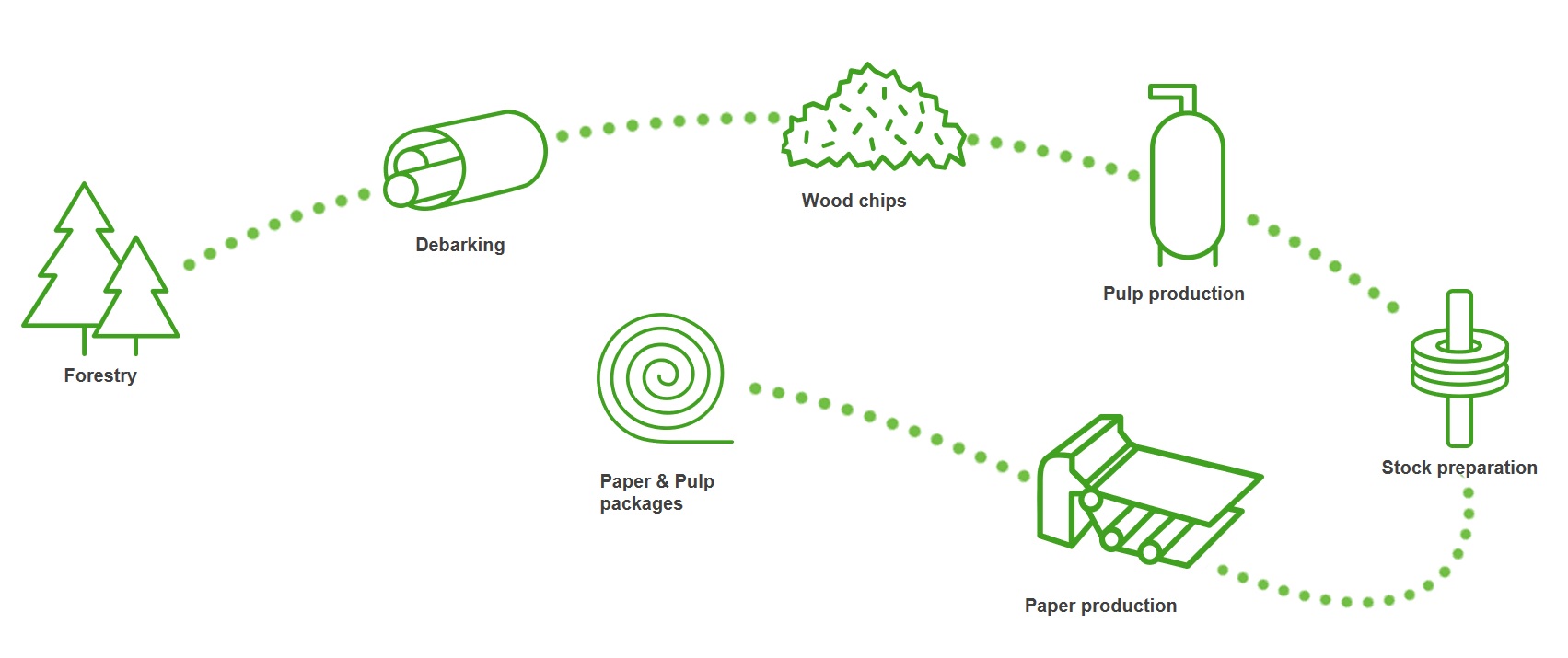

An integrated paper mill has the necessary on-site capabilities to convert round wood (ie trees & branches) first into pulp, and then into paper. Integrated paper mills are usually found close to the essential resources they need, mainly timber and water.

Integrated paper production is very cost effective. For example, the bark stripped from the wood used is converted into biomass and used to generate the power needed to produce the paper. In fact, a modern, integrated mill can be up to 95% energy self-sufficient. In addition, unused heat from the mill is supplied to the local community to heat their homes.

Non-integrated Paper Mills

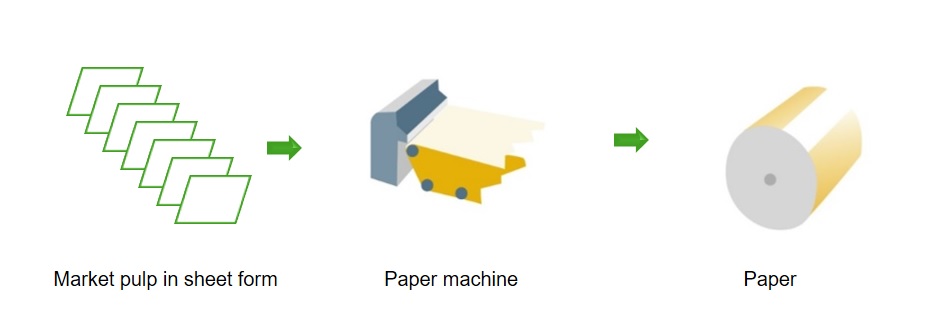

By contrast, a non-integrated paper mill uses dried pulp as the starting point for paper making. Dried pulp is made in special machines at integrated mills or at non-integrated pulp mills and sold on the open market.

While integrated mills offer the very highest levels of cost effectiveness and efficiency, they are less flexible than non-integrated mills since they are set-up for very high production. Integrated mills are also usually limited to using wood from relatively local forests.

Non-integrated mills can never be as cost effective as integrated mills, but they can use pulp from anywhere in the world and are therefore able to achieve a more complex blend of fibres to give beneficial properties. Non-integrated mills also typically have lower minimum order quantities since they are batch processes, and they can utilise more non-cellulosic additives which are not suited to integrated paper making. Lastly, medical packaging papers intended for steam sterilisation benefit from being manufactured from dried pulp.

In the end, integrated and non-integrated paper production are complementary to each other, and a paper maker with both is best set up to support customers whatever their requirements.

Billerud has a wealth of expertise and experience in paper packaging for medical devices. For more on MG papers, download a recording of our webinar HOW MG PAPER IS MADE.

A great way to stay up-to-date on everything from paper-making basics to the latest developments in the industry is to sign up to receive blog updates and info about upcoming webinars.